2.3.4 Use of Expansion Loops in Piping Design & Stress Analysis

- Meena Rezkallah, P.Eng.

- Jun 3, 2020

- 1 min read

Updated: Dec 19, 2020

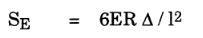

In the event that model refinement is not sufficient to solve the problem (i.e., there is a real problem, and not just one on paper), something must be done. Re-examining the equation for the guided cantilever model:

It is evident that the stress analyst cannot easily change the terms 6, E, R, or delta. This leaves only 1, the length of the leg absorbing the thermal growth. This can be done through the addition of an expansion loop. In this case, the thermal growth is partially absorbed by each of the legs running orthogonally to the thermal growth:

The stress range calculated in the longer leg is only 3937 psi (note that the maximum expansion stress is found in the longest leg resisting the displacement), compared to 17,700 psi without the loop. Generically, the stress range in a leg j, due to thermal expansion in a direction perpendicular to that of leg j, is:

Therefore, the calculated stress range should always decrease if expansion loops are added in any direction perpendicular to a direction of thermal growth, since the denominator in the expression for the expansion stress will increase.

Read More:

To get our piping stress analysis services, please contact our piping engineering firm for a free quote.